Opportunity

It is possible to fundamentally reduce heavy industries' contribution to our climate challenges. The green transition needs new technologies, industry innovations, and new cooperation in order to succeed. SaltX Technology and SMA Mineral joined forces to provide a solution that could revolutionize the lime industry. In order to spread awareness, knowledge, finance, and build new factories, SaltX Technology and SMA created a common platform under the name ZEQL.

The New Division was asked to be the partner on the brand journey. Together, we created a brand that explains and positions quicklime as an essential part of Sweden's green transition. This journey included comprehensive brand platform development, reference group facilitation, and an official launch event.

Process

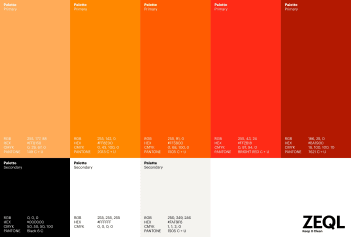

We created an original brand platform encompassing a name, visual identity, logo, story, film, webpage, and illustrations to communicate the innovation. Our approach involved workshops, interviews, and regular engagements with SMA, SaltX, as well as external stakeholders, gathering insights on the innovation, collaboration narratives, and visual cues.

This process led to formulating a Vision, Mission, Purpose, tagline, and the brand concept: "ZEQL - Keep it Clean." ZEQL, the abbreviation for Zero Emission QuickLime.

To validate the brand and story, TND organized and facilitated a reference group involving industry peers and external stakeholders, providing valuable input. In addition, we supported SaltX and SMA in producing the official global brand launch event.

Change

ZEQL is based on industry collaboration and sharing in order to drive change in the whole supply chain within and around the adjacent industries. ZEQL has the potential to eliminate 8% of global CO2 emissions through the unique solution where fossil fuels are replaced with electricity and CO2 is captured directly in the heating process; the solution is one of its kind globally. No additional CCS plant is required. In addition, the production is more resource and energy-efficient than traditional quicklime production.